|

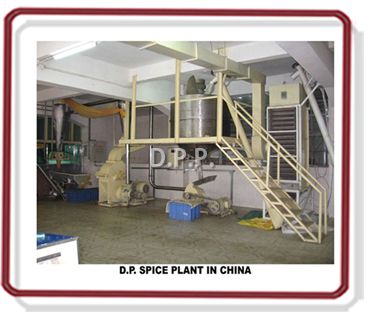

Spice Grinding Plant System |

We have three types of pulverizers to offer you for the grinding of spices as under :-

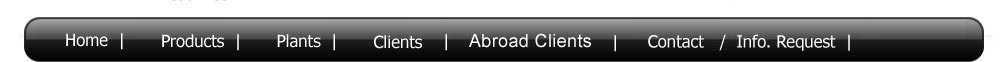

1. D. P. Mini pulverizer is a very simple type of pulverizer. The grinding chamber consists of a serrated ratchet liner on top,

and screen at the bottom for classification. Feed material is passed into grinding chamber through a hopper manually.

The ground power is collected in a through fitted below the screen, depending on the desired fineness, the number of

operations could be 2 or 3 in different types of sieves.

During the grinding process, a small quantity of air is generated, to remove this air a Polyester dust bag is fixed below

the

through and the other end of the bag is hung at a height, also acting like a dust collector.

Our D.P. Mini Pulverizers are exclusively ideal for the grinding of small quantity of spices, especially for high value condiments like, cinnamon, cloves, cardamom, nutmeg, pulses, sugar with a capacity from 5 Kgs. To 60 Kgs. Per hour, more ever this machine is also highly capable of grinding wet and pulpy material, like green/red chilly sauce, fresh ginger garlic paste, and other wet and allied food products. The attached illustrated & informative catalog of D.P. Mini Pulverizer attached over separate following e-mails will give you a thorough idea of the type of equipment manufactured by us. We give here below production figures for the same :-

H. P. Required Production Per Hour Approximately

|

Size of Machine |

D.P.M. - 6 Mini Pulverizer 2 H.P. |

8 - 12 Kgs. |

D.P.M. - 7 Mini Pulverizer 3 H.P |

15 - 20 Kgs. |

D.P.M. - 8 Mini Pulverizer 5 H.P. |

20 - 25 Kgs |

D.P.M. - 12 Mini Pulverizer 10 H.P. |

55 - 60 Kgs. |

|

2. Our D.P. Hammer Mill (Screen type Machine) is more efficient than compared to the Mini Pulverizer, with better grinding efficiency. The grinding chamber consists of a serrated liner on top and screen at the bottom, a blower is fitted to suck the ground powder, below the screen driven on the same shaft. At times due to higher oil content in spices, there are chances of the screen getting clogged with spices, thus chocking the grinding chamber. The material passes through the blower and gets discharged through the cyclone through a one way valve. The air generated in the grinding chamber passes out through the cyclone outlet on top. A Polyester dust bag can be fitted above the cyclone working like a dust collector, or we can offer you a totally enclosed dust collector (manually shaken type) or a pulse air type dust collector, the choice we however leave it to your kind decision. The attached illustrated catalog will also brief you about the type of machine manufactured by us

|

|

Our D.P. Hammer Mills are exclusively meant for the grinding of Chillies, Coriander, Dry ginger, Black Pepper, Turmeric and Curry powders, on a large scale basis. These spices are ground in a two / three stage operation, depending on the fineness desired, i.e. The breaking of the spice in a large hole screen for the first operation, and the subsequent fine grinding done in a fine hole screen for the second and third operation. We give here below production figures for the same. |

Size of Machine |

H.P. Required |

Blower

H. P |

Production

Per

8 Hours

Approximately |

DPHM -10

Hammer Mill |

10 H.P |

- |

350 - 400 Kgs |

DPHM -20

Hammer Mill |

20 H.P |

- |

700 - 800 Kgs |

DPHM -40

Hammer Mil |

40 H.P. |

- |

1400 - 1600 Kgs |

DPHM -50

Hammer Mill |

50 H.P. |

7.5 |

2500 - 2750 Kgs |

DPHM -80

Hammer Mill |

80 H.P |

10 |

3600 - 4000 Kgs. |

|

3. Our D.P. Impact Pulverizer (screen less type) is for the grinding of Turmeric, Pepper in one operation.

We give here below the production figures for the same |

|

|

|

|

|